Expertise & Consulting

BETA BEAMS offers feasibility studies to help its customers determine the technical parameters of their equipment for e-beam product treatment.

- Evaluation of feasibility and of the concept of product treatment

- Size calculation and design of shielding

- Comparison of simulation results with tests on equipment available at BETA BEAMS

- Provision of a class 1 laboratory to perform test on biological indicators.

The teams at BETA BEAMS have the necessary expertise and tools to design e-beam equipment in order to help customers in the development and definition of machine parameters.

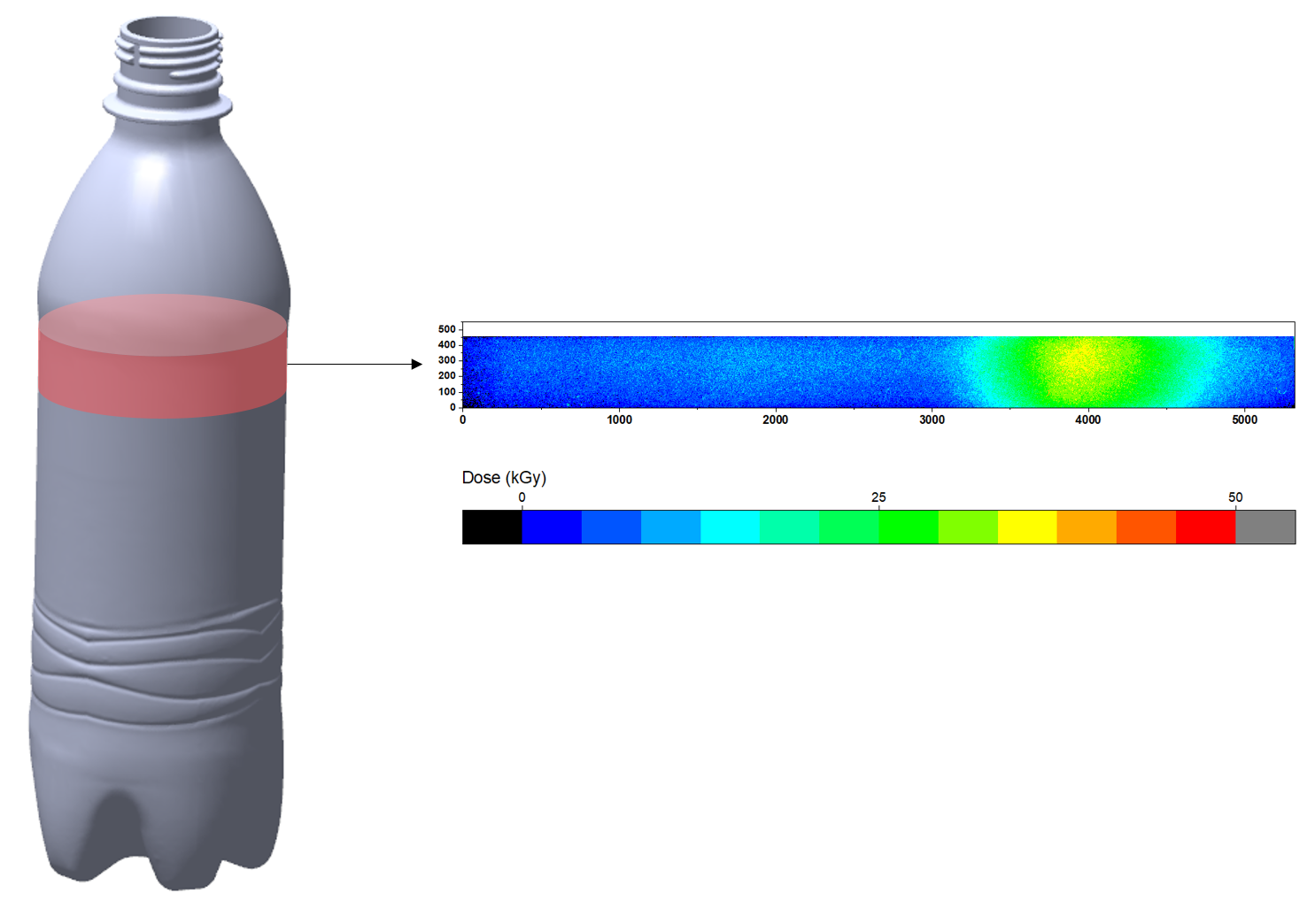

Simulation

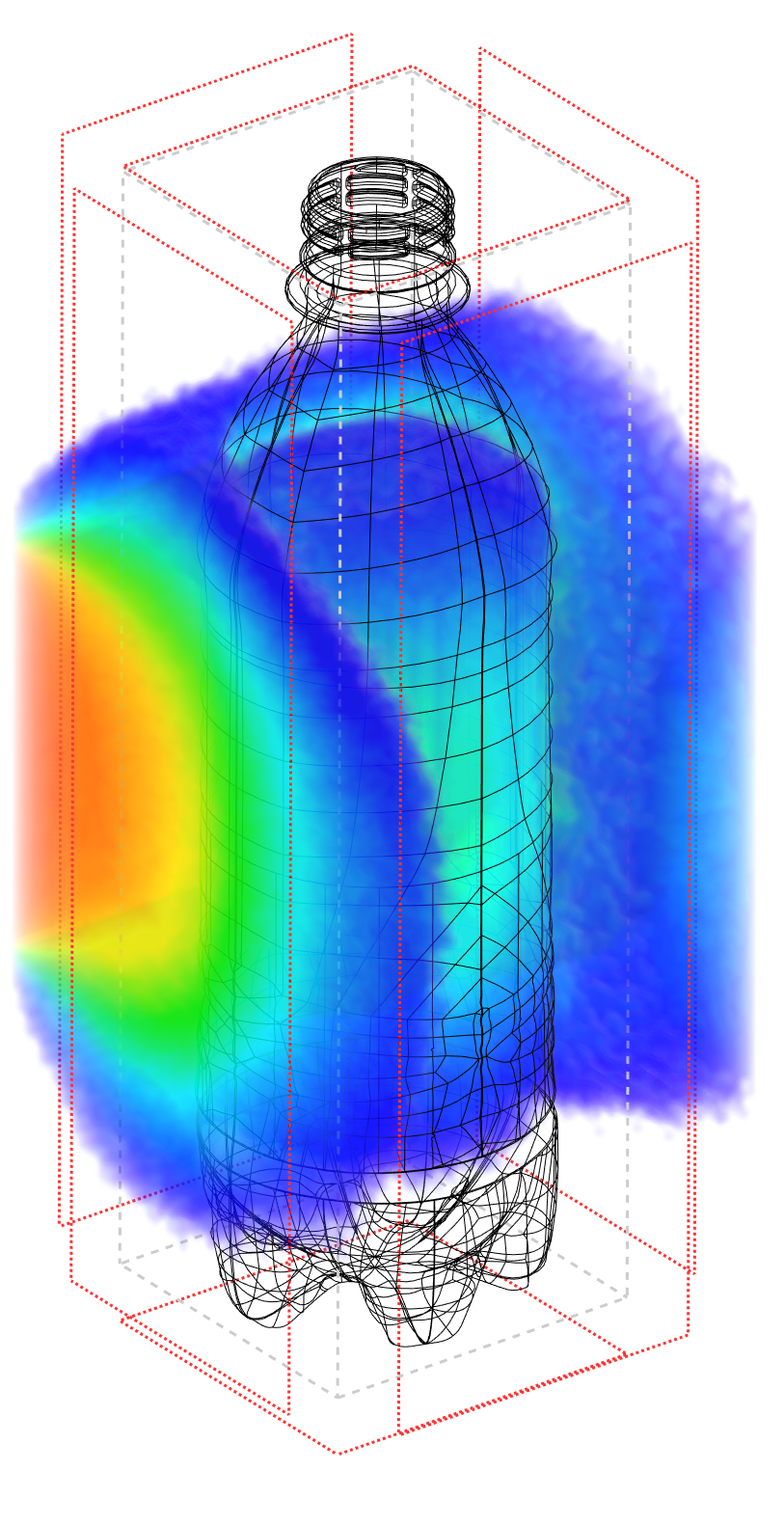

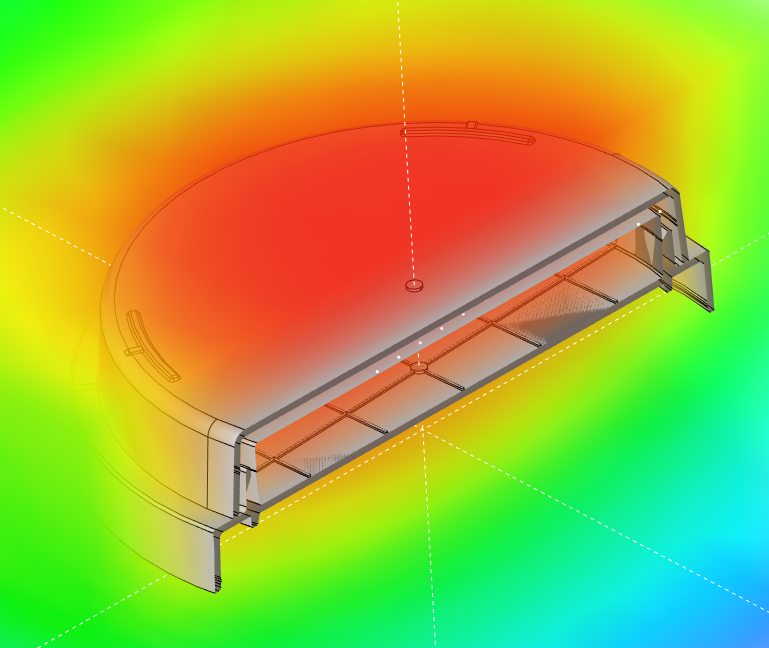

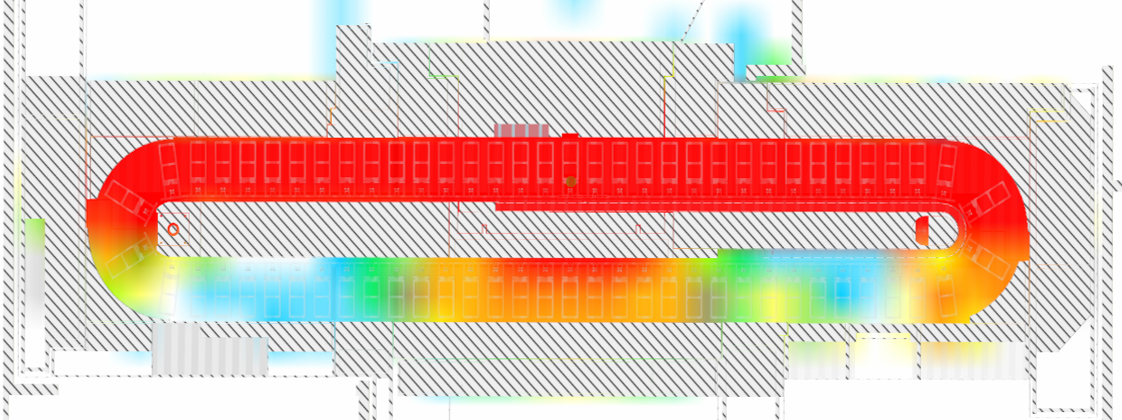

BETA BEAMS masters the tools to model and determine the distribution of the dose on the given product:

- Identify the critical zones of the product

- Determine the energy required to meet the product constraints

- Dose mapping by simulation to guarantee that the minimum and maximum doses meet the client’s expectations, regardless of the product’s complexity (use of the client’s step files)

- Determine beam shape, treatment configuration and machine power to meet customer specifications

Radioprotection

BETA BEAMS has a 3D modeling software dedicated to medical applications, which enables the calculation of size for the system’s self-shielding.

BETA BEAMS has a simulation team working in close collaboration with its engineering office in order to offer the customer a solution best adapted to the end environment of installation.

BETA BEAMS guarantees the operators a safe working environment, in accordance with safety standards (NF C-15 160, NF C 15-164, NF C 74-100 and NF M 62-105).

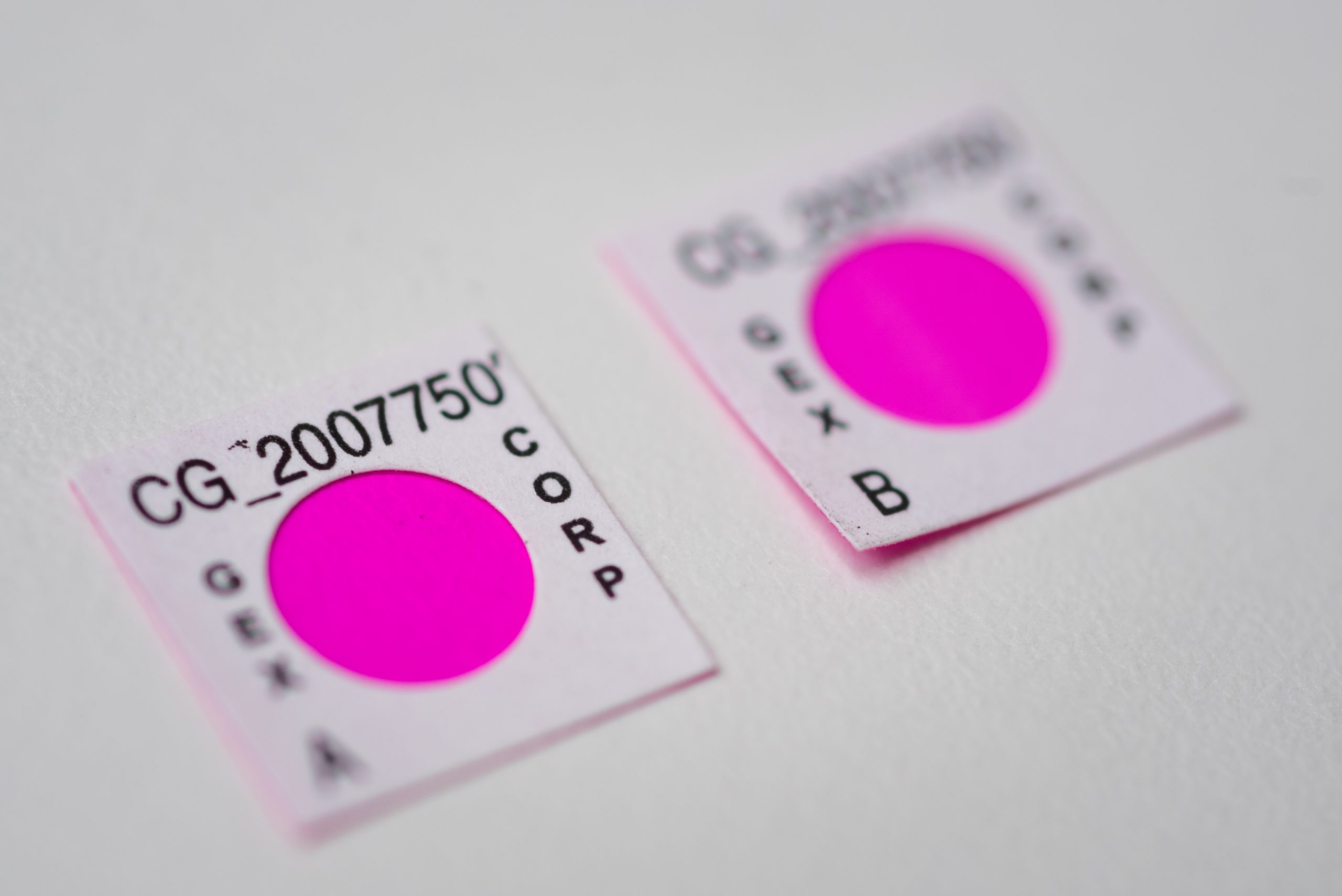

Dosimetry

BETA BEAMS has two resources allowing it to offer different dosimetric approaches.

Dosimeters are used to confirm that:

- the minimum dose is reached on all surfaces of the product to be treated and to guarantee the expected sterility assurance level (SAL).

- the maximum dose above which harmful effects occur is not exceeded.